How it works

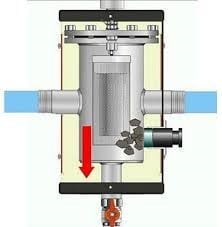

The function is based on the cathodic-anodic principle, letting a less noble metal (magnesium) corrode instead of the system itself. During that process oxygen in the water is absorbed, creating H2O and magnesium hydroxide. Consequently, the entire system is protected from corrosion, even aluminium and aluminium alloys, without using any chemicals.